Introduction to Laser Cutting Acrylic

Laser cutting acrylic is a transformative process that provides unmatched accuracy and flexibility in the creation of intricate designs and precise cuts. This method utilizes a high-powered laser beam to slice through acrylic material, melting and vaporizing the acrylic where the laser beam contacts the surface. As a result, it leaves a smooth, polished edge that is often free from any additional finishing requirements. The technology is ideal for both large-scale production and detailed custom projects. With its ability to cut with minimal waste and its efficiency in fast turnaround times, laser cutting is increasingly favored over traditional methods like mechanical cutting or manual carving.

Moreover, the versatility of laser cutting extends beyond simple cuts. It can also be used to engrave detailed patterns and textures onto acrylic surfaces, adding depth and complexity to any piece. This dual capability of cutting and engraving makes laser cutting a preferred choice for projects that require high levels of customization and artistic expression. Whether for commercial or artistic applications, the precision of laser cutting ensures that every detail of the original design is captured perfectly in the final product.

How Laser Cutting Works

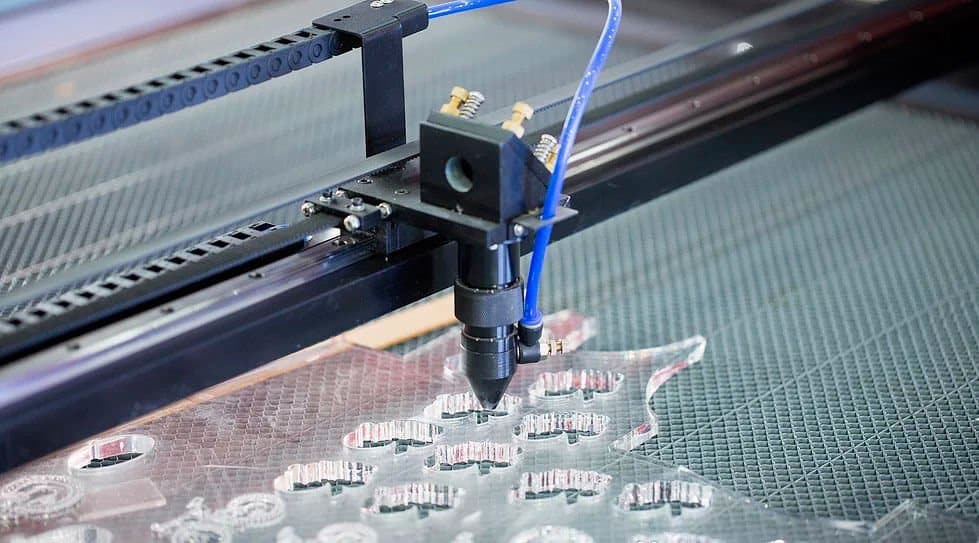

At the core of laser cutting technology lies the laser cutter, a machine that directs a powerful laser beam precisely at the acrylic. The machine typically uses a CO2 laser, known for its efficiency in cutting non-metal materials like acrylic. The process starts when a digital design is sent to the laser cutter’s computer system. This design acts as a guide for the laser, which follows the path outlined by the digital file. As the laser moves across the acrylic, it vaporizes the material, leaving a clean and precise cut with smooth edges. This method is not only fast but also incredibly consistent, making it ideal for producing multiple copies of the same design with exact precision.

The precision of laser cutting also allows for the minimization of material waste, which is a significant benefit for both cost control and environmental sustainability. The accuracy of the laser beam means that cuts are only made where necessary, reducing excess waste and enabling the use of remaining acrylic pieces for smaller projects. This efficiency is crucial for businesses looking to optimize their production processes and reduce overall material costs.

Benefits of Using Laser Cutting for Acrylic

Laser cutting offers numerous benefits when it comes to working with acrylic, a versatile and widely used material in numerous industries. This advanced technology enhances both the quality and the efficiency of the cutting process, providing cleaner cuts with greater detail than traditional methods. From its ability to handle intricate designs to its consistency across large volumes, laser cutting acrylic is transforming how businesses and creatives approach projects involving acrylic.

Precision and Accuracy

One of the most significant advantages of using laser cutting acrylic is its precision. The laser beam can make extremely fine cuts, allowing for the creation of intricate designs that would be difficult or impossible to achieve with traditional cutting methods. This precision makes laser cutting ideal for detailed logos, delicate inlays, and precise architectural models. It ensures that even the most complex patterns are executed with sharp clarity and exact alignment, enhancing the overall quality and appearance of the final product.

Versatility in Design

Laser cutting acrylic technology supports a wide range of design possibilities. Unlike mechanical cutting tools which may be limited by blade size and shape, the laser beam can easily create complex and detailed cuts without changing any tools. This capability allows designers to experiment with various shapes and patterns, from simple geometric forms to elaborate artistic motifs. Additionally, the ability to adjust the intensity and speed of the laser means that it can be adapted to cut through different thicknesses of acrylic, further increasing the versatility of this method.

Applications of Laser Cut Acrylic

Acrylic’s unique properties, such as its clarity, durability, and versatility, make it an ideal candidate for various applications that benefit from precision cutting. Laser cut acrylic is extensively used in a range of industries, from advertising to the arts. This section explores the diverse applications of laser-cut acrylic, highlighting how this technology is integral in fields that require precision and aesthetic appeal.

Signage and Display

Acrylic is a popular choice for signage and displays due to its clarity and durability. Laser cutting acrylic allows for the production of eye-catching signs that can withstand the elements without losing color or clarity. Businesses frequently use laser-cut acrylic for outdoor signs, shop displays, and directional signage. The material’s resistance to weather and UV radiation makes it an excellent choice for long-lasting, vibrant signage that captures attention and directs customer flow.

Decorative Items and Art

Artists and designers often choose acrylic for decorative projects because of its smooth finish and glass-like appearance. Laser cutting can be used to produce intricate artwork, jewelry, and home decor items. These products benefit from the clean cuts and polished edges that the laser provides. The ability to precisely cut detailed designs also allows artists to push the boundaries of their creativity, experimenting with light and shadow effects that enhance the aesthetic appeal of their artworks.

Challenges and Considerations

While laser cutting is a powerful tool for shaping acrylic, it comes with its own set of challenges and considerations that must be managed to maximize the potential of this technology. From technical limitations to safety concerns, understanding these factors is essential for anyone looking to utilize laser cutting in their projects. This knowledge ensures not only the quality of the finished pieces but also the safety and efficiency of the cutting process itself.

Material Limitations

While acrylic is versatile and useful, it has its limitations. It can be susceptible to cracking and stress if not handled properly. Furthermore, the laser cutting acrylic process requires careful setup to avoid burning or excessive melting of the acrylic. Proper calibration of the laser cutter is crucial to prevent damage to the material, ensuring that each cut is clean and consistent. Technicians must be well-trained to understand the properties of acrylic and how it reacts under different cutting conditions to optimize the quality of the final product.

Safety Measures

The process of laser cutting acrylic generates fumes that can be harmful if inhaled. It’s crucial to use proper ventilation systems and follow safety protocols to ensure a safe working environment for operators. Additionally, the intense laser beam presents a risk of burns or other injuries if proper safety measures are not in place. Operators must use protective equipment and adhere to strict safety guidelines to minimize the risk of accidents during the cutting process.

Conclusion: Why Choose Acrylics By Design for Your Laser Cutting Acrylic Needs

At Acrylics By Design, we are not just a service provider; we are your partners in bringing visions to life through laser cutting. Our state-of-the-art laser cutters and experienced technicians ensure precision in every project, whether it’s complex industrial components or intricate artistic creations. We understand the nuances of working with acrylic, and we commit to delivering products that meet the highest standards of quality and durability. Choose Acrylics By Design, where your designs are not just made, but crafted with precision and care. Trust us to turn your creative ideas into stunning realities.